A practitioner’s view from four decades in beverage manufacturing on why sustainability is hardest and most necessary for SMEs.

In my 40+ years of career, I have worked in beverage companies for 30 years. And when you are in this field, you develop a strong admiration for your main, and largest by quantity, ingredient: water.

When I joined United Breweries in 2004 as the Plant Head for one of their recently acquired breweries near Delhi, we were struggling with high water consumption and, as a result, high wastewater discharge. The groundwater was depleting; whatever drops remained had excessive levels of dissolved minerals and were thus unsuitable for brewing beer. The situation was so grim that we risked abandoning the site and relocating to a new one if it wasn't rectified. And trust me establishing a new brewery is not easy! The capital expenditures are high, and there is a risk of losing out on an established market—an unthinkable consequence.

To reverse the imminent danger of a dry spell, we set up a focus group centered on reducing water wastage and replenishing groundwater. We adopted the best practices with the right people, processes, and equipment to back it up. It was a long journey, at least two or three years, but the positive results were far more important. It kick-started my love for developing sustainable operations.

The following year, I was promoted and given the additional charge of reducing water consumption across all 21 breweries in the country. Along the way, I started paying attention to energy and corporate social responsibility, too. In 2015, as I adopted the UN’s Sustainable Development Goals, my focus became more holistic to include ESG (Environment, Social, and Governance) — a learning which remained with me even as I changed various organizations. It is during these years that I learned of the difficulties encountered by start-ups and smaller organizations.

As of today, Micro, Small, and Medium Enterprises (MSMEs) represent over 90% of businesses, employing up to 70% of the workforce and driving around half of the world’s GDP. Even though accurate global figures vary, India alone sees MSMEs contributing approximately 30% to GDP and roughly 45% to exports, highlighting MSMEs’ key role in job creation, innovation, and sustainable development worldwide.

A 23 June 2025 World Economic Forum white paper, Sustainability Meets Growth: A Roadmap for SMEs and Mid-Sized Manufacturers, makes a useful point: small and mid-sized manufacturers can be powerful multipliers of climate action, particularly in decarbonizing value chains because they sit inside global supply networks. The report also indicates that fast-tracking sustainability transitions by SMEs can materially improve progress toward Paris Agreement goals while unlocking economic growth.

According to a 2015 estimate by the International Energy Agency (IEA), SMEs account for 13% of the world’s total carbon emissions. If one only looks at carbon emissions by the business sector, SMEs account for 60% (recently, a report by the World Economic Forum and the Organization for Economic Co-operation and Development (OECD), dated 23 June 2025, found this segment accounted for 40-60% of the total carbon emissions by businesses). In India, the overall greenhouse gas emissions by SMEs are around 110–150 million tonnes of CO₂, accounting for roughly 10–15% of the total emissions by the country’s industrial sector.

So why the hesitation?

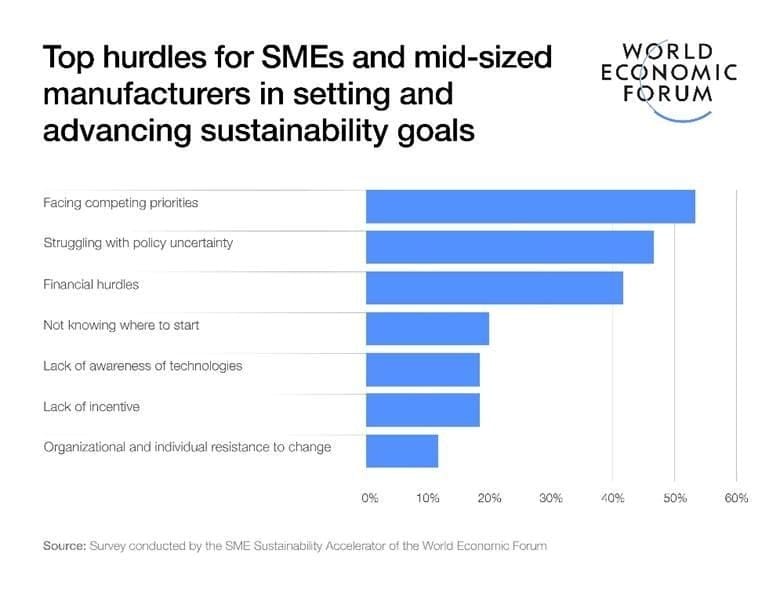

Running an SME is rife with problems. Investments are largely operational forward, focused on infrastructure, selling, and marketing costs. Due to tight cash flows, one is often hesitant to invest in anything that takes one or two years for payback. It may take years for the financial benefits of sustainability investments (such as cost savings, strengthened brand reputation, and risk mitigation) to be realized. Add to this the lack of clarity regarding which technologies or processes will prove effective for sustainability, leading to uncertainty of stable government policies and incentives. With no historical data to prove effectiveness and difficulties measuring non financial benefits, such as risk mitigation and company image within existing financial modules, investors and business owners perceive investing in green technologies as risky.

The hurdles start at the bottom. Often, SMEs don’t hire people who specialize in sustainability, which leads to a huge gap in knowledge and skill; reducing manpower and focusing on ‘core’ operations takes precedence. At the top rung, too, owners and leaders don’t commit to sustainability due to insufficient awareness and priority. It is owing to this lack of expertise in the domain that dedicated departments are considered responsible and capable of providing sustainability solutions. The rest of the organization remains in silos.

And that’s where the problem lies. Sustainability requires collaboration across the organization, as it requires looking at ESG holistically. Highly collaborative teams are key to ESG solutions.

What’s in it for (S)Me?

Regulatory compliance may not be the ideal motivation, but it is the most effective. For SMEs, these key compliance requirements include controlling emissions of water, gas, and solid waste. On the social front, this includes workers’ health and safety measures, a crèche for children, and more. The hazards and norms depend upon the severity of operations and the industry. These steps should not be taken retroactively, though. Authorities should monitor installations during the project stage rather than at completion. Often, entire costs have sunk towards the penultimate steps.

Before starting a Greenfield manufacturing project, one has to obtain a ‘Consent to Establish’ for emission control measures from the regulatory authorities. The next contact with authorities, then, is only at the time of completion, when a ‘Consent to Operate’ must be obtained. If the constructed parameters do not comply with the norms, modifications to the construction can be made and resubmitted to the authorities for approval. Sadly, these processes can be long and expensive. I feel authorities can lend a helping hand here by introducing stage-wise inspections.

Financial benefits are another motivator. By adopting best practices, one can notably reduce the cost of sustainability initiatives. Many large organizations have cells centered on developing training tools and process enhancements. These measures help reduce waste, thereby diminishing the need for capital investment.

Technology and costs

The cost of green technology also continuously decreases with scale, thereby reducing payback periods. According to Wright’s Law, from 2009 to 2019, there has been a steep drop in green technology prices due to increased production scale and innovation. In 2024, it is cheaper to increase renewable power generation capacities by up to 90% than the cheapest available new fossil fuel-based alternatives.

Source: https://www.solarpowerportal.co.uk/solar-pv/solar-pv-costs-fall-82-over-the-last-decade-says-irena)

Sustainability is an increasingly powerful marketing tool. Today, consumers favor companies that show authentic ESG responsibilities. By attracting eco conscious consumers, companies can build strong brand loyalty, enhance their reputation, and promote innovation through aligning profit with purpose. It is important to move beyond green-washing to authentic action. A powerful mix combines regulatory compulsion softened by incentives, financial gains, and improved brand image.

The next step

The best, most effective, and quickest way to achieve sustainability targets with minimal capital investment is to reduce waste, ensure compliance with best practice work processes, and make smart investments in effective technologies. Start with what you can measure and control: specific water use (hl/hl), specific energy (kWh/hl), and unplanned downtime minutes. Add a few meters and controls, create a weekly dashboard, and let cross-departmental teams act on the data. Strong, progressive leadership, combined with clear direction, ethical practices, and a long-term focus, is also a must. It requires building an empowered workforce by continuously developing in-house talent, encouraging input across all levels, and seeding agents who train larger groups down the pyramid. These personnel can focus on lean processes, quality assurance, and cost-efficient logistics.

Sustainability isn’t only viable for smaller manufacturers; it can also be leveraged as a competitive advantage in today’s fast-evolving economic and regulatory setting. All one needs to do is take the first step.